We are looking for a long-term Hydraulic Engineer to join our tightly-knit, family-run business, which holds value in every employee that works towards both their own and the company’s goals. Our company specializes in the design, manufacture, modification, and repair of a wide range of heavy material handling equipment, for companies within the UK and across Globe. With our expertise and knowledge, we provide a bespoke material handling service like no other, working alongside all WRS’s engineering departments, we research, design, and modify/manufacture bespoke lifting equipment to best fulfill the world's need for innovation, and implementation of new and repurposed lifting equipment.

Your duties and responsibilities will include.

you will be required to;

Ability and knowledge

Preferred ability and knowledge

What we offer

for candidates who do not yet meet these standards, training and development will be implemented before full wage can be offered.

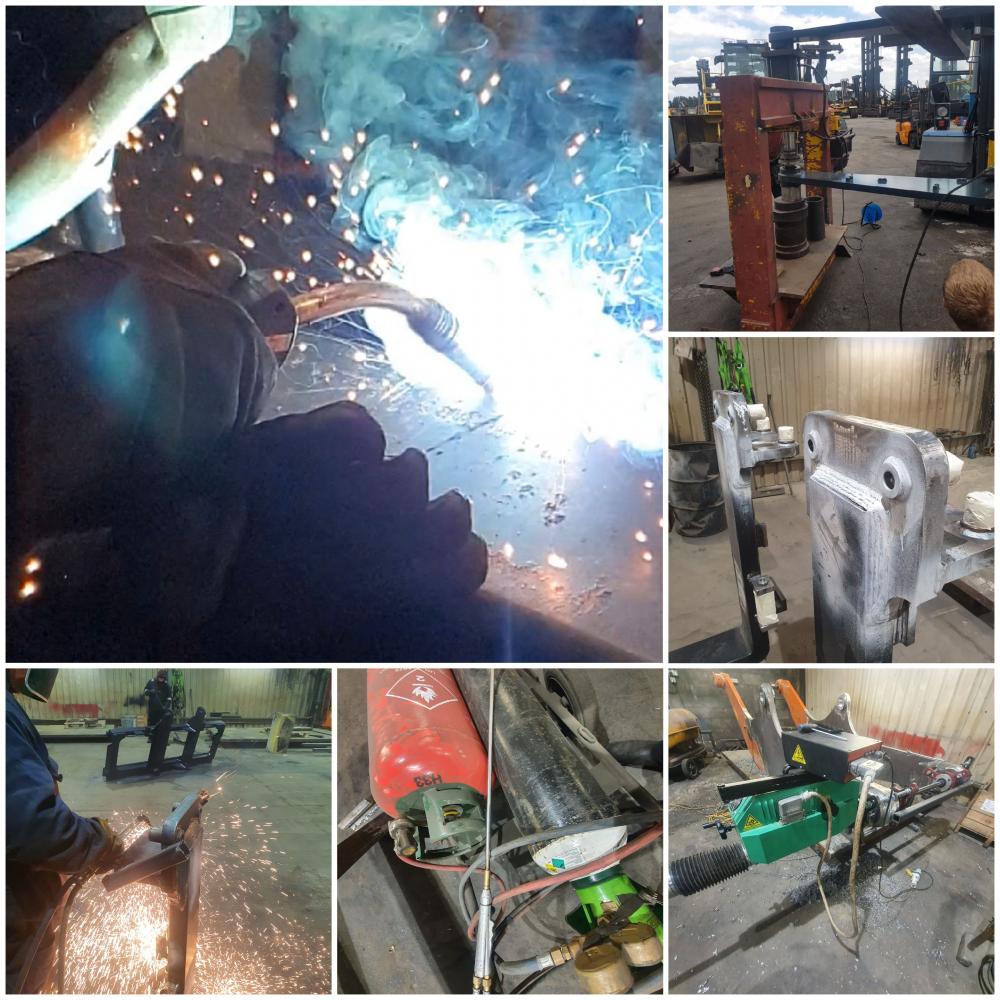

We are looking for a long-term fabricator/welder to join our tightly-knit, family-run business, which holds value in every employee that works towards both their own and the company’s goals. Our company specializes in the design, manufacture, modification, and repair of a wide range of heavy material handling equipment, for companies within the UK and across Globe. With our expertise and knowledge, we provide a bespoke material handling service like no other, working alongside all WRS’s engineering departments, we research, design, and modify/manufacture bespoke lifting equipment to best fulfill the worlds need for innovation and implementation of new and/or repurposed lifting equipment.

Your duties and responsibilities will include.

you will be required to;

Ability and knowledge

Preferred ability and knowledge

What we offer

£15.50 P/H

40 hour weeks, + Overtime

Monday to Friday

08:00 – 16:30

Average holiday pay,

Enhanced holidays for loyalty, 1 every 2 years 5 days total

Annual £1,000 bonus

£32,240.00 - £50,375.00 with overtime

Training in every department

Flexible workweek when required

for candidates which do not yet meet these standards, training and development will be implemented before full wage can be offered.

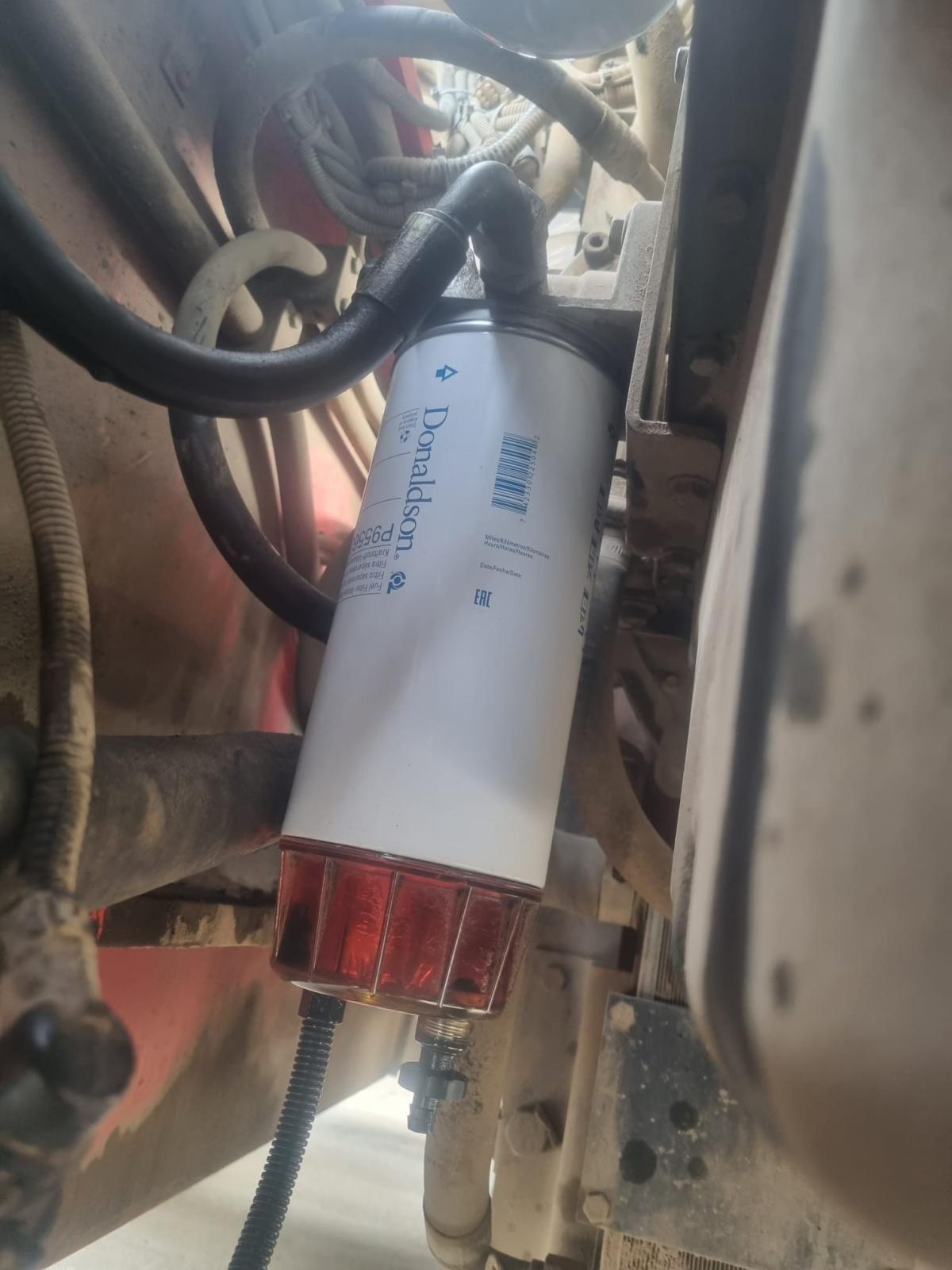

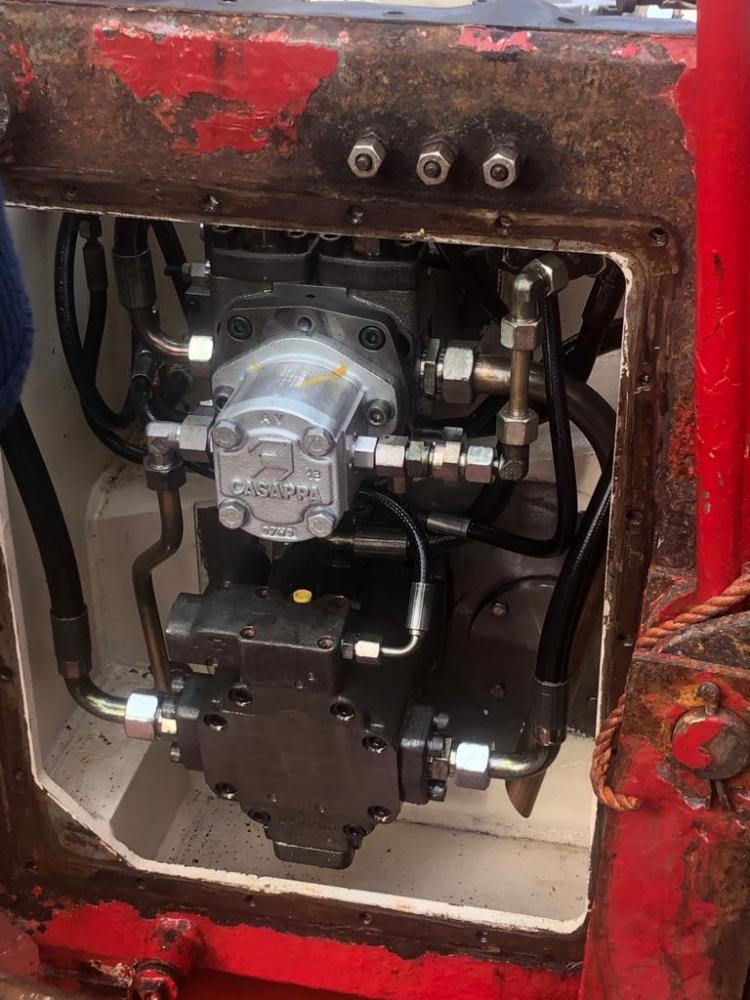

Wide Range After Sales Service,

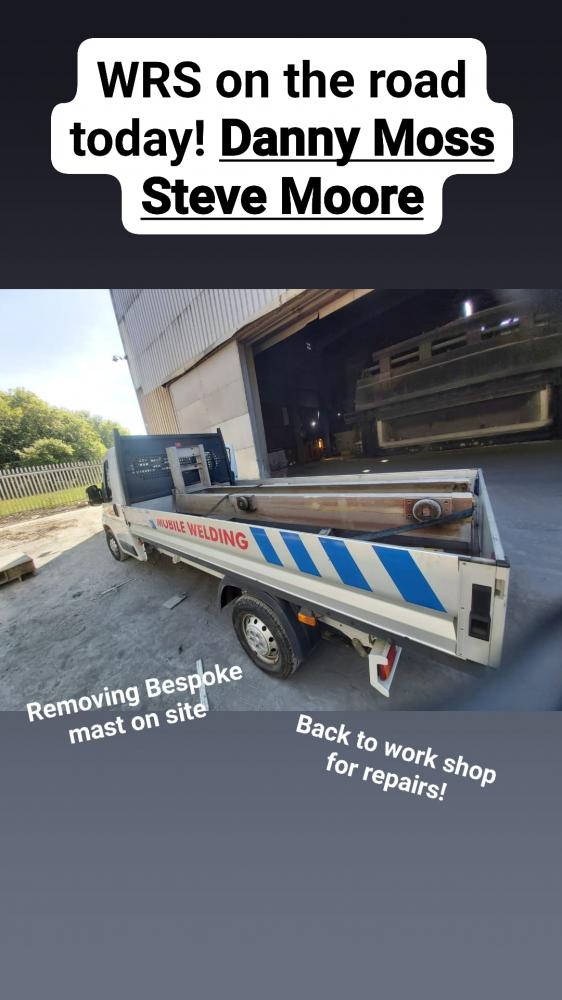

Wide Range After Sales Service,Sending our onsite service van to local machine sale customers, ensuring they are happy with the slae, and that their machine continues to operate as it should.

Here we managed to perform our annual service,

Here we managed to perform our annual service,

Replacing filters, hoses and any other faults we could find.

Replacing filters, hoses and any other faults we could find.

Here at Wide Range, we continue our service beyond the point of sale!

Here at Wide Range, we continue our service beyond the point of sale!

offering all our services,

Hydraulic,

Fabrication,

Mechanical,

and Machining!

We are looking for a long-term Forklift Mechanic to join our tightly-knit, family-run business, which holds value in every employee that works towards both their own and the company’s goals. Our company specializes in the design, manufacture, modification, and repair of a wide range of heavy material handling equipment, for companies within the UK and across Globe. With our expertise and knowledge, we provide a bespoke material handling service like no other, working alongside all WRS’s engineering departments, we research, design, and modify/manufacture bespoke lifting equipment to best fulfill the world's need for innovation, and implementation of new and repurposed lifting equipment.

Your duties and responsibilities will include.

for candidates who do not yet meet these standards, training and development will be implemented before full wage can be offered.

Josh: 07801746513 / Josh@wrshull.co.uk

Northfield Engineering also incorporates East Coast Fluid Power, a company that offers Hydraulic Equipment, Oil, and Fittings for purchase -

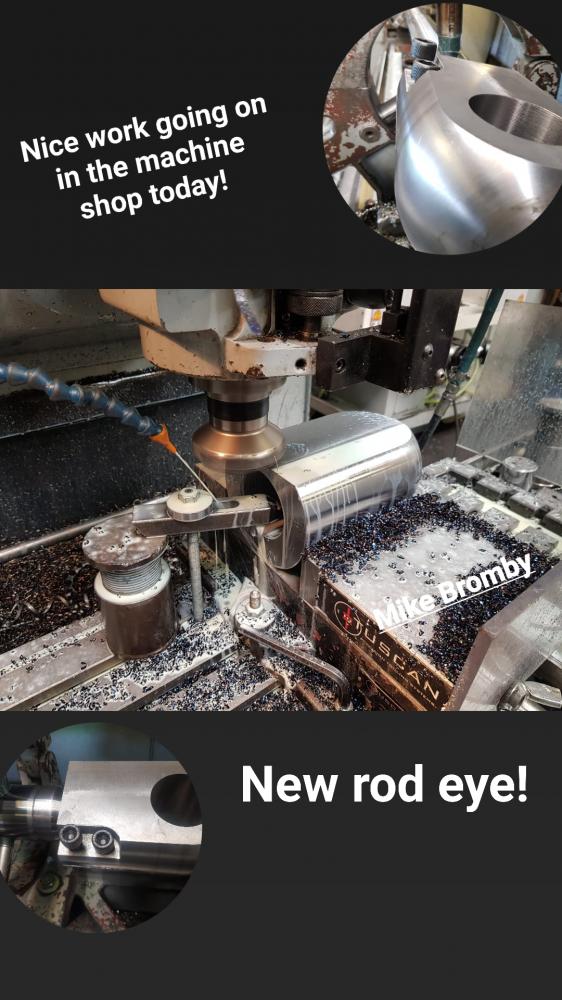

Our machine shop is on hand to manufacture any replacement parts you need, from pins and bushes, to complete new hydraulic cylinders parts, either pattern replacements, or new improved components. see more on our machining services here

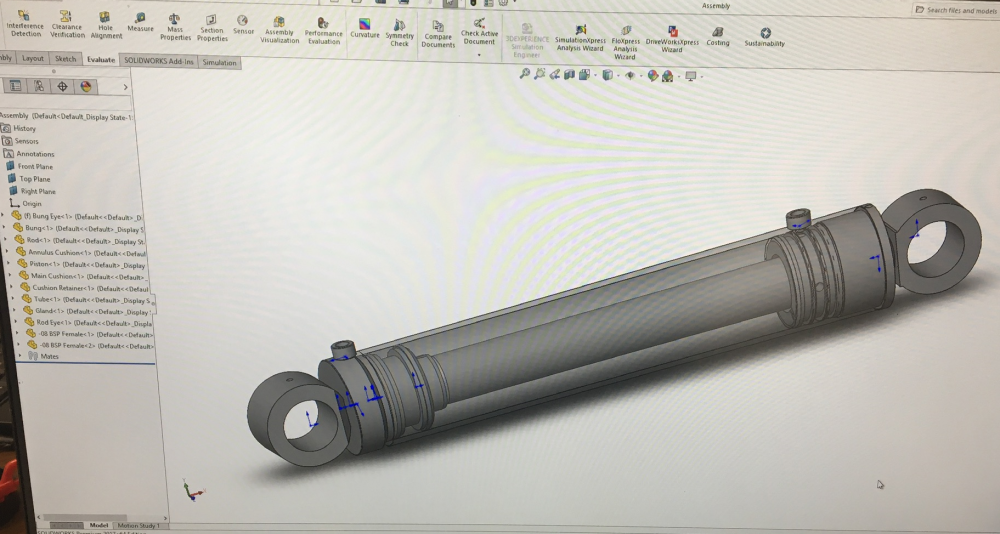

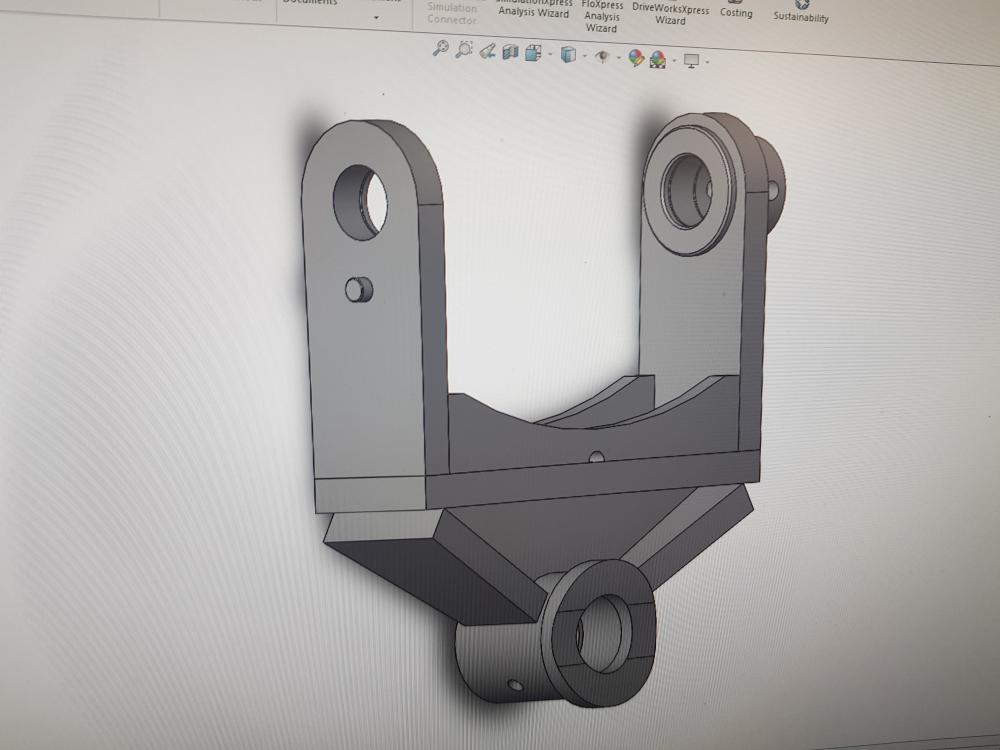

Danny moss also designs complete cylinders to meet your needs, using SOLID WORKS we are able to prototype cylinders to suit almost any purpose, from telescopic Olympic lifting stages to adding new functionality to our local farmer's tractor attachments, and of course our vast stock of Material Handling Equipment.

We keep a huge stock of hydraulic cylinder material and hydraulic components in order to offer an immediate hydraulic repair service, we have the following on stock -

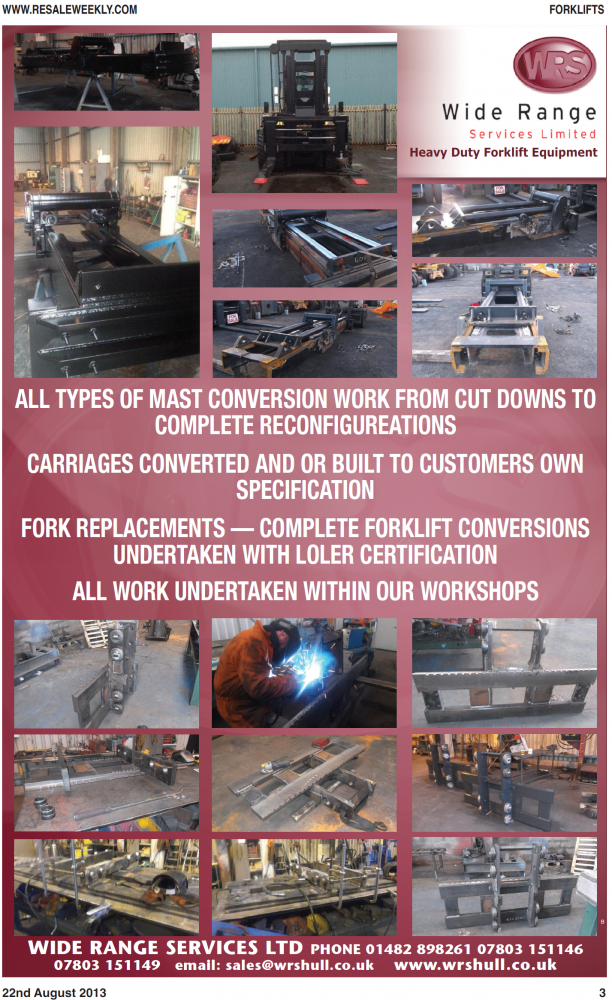

The first seven years saw a consolidation of operations culminating in 2012 with the completion of the new machine shop and mechanical workshop. WRS now has 14,000 square feet of the workshop including a fully equipped machine shop, hydraulic shop, two forklift refurbishment workshops, and a fabrication & welding workshop, along with 2 acres of yard storage, allowing us to expand our equipment sales. All of this combined enables WRS to supply equipment both standard or adapted to fit any individual's specification for both trade and end-users alike.

The first seven years saw a consolidation of operations culminating in 2012 with the completion of the new machine shop and mechanical workshop. WRS now has 14,000 square feet of the workshop including a fully equipped machine shop, hydraulic shop, two forklift refurbishment workshops, and a fabrication & welding workshop, along with 2 acres of yard storage, allowing us to expand our equipment sales. All of this combined enables WRS to supply equipment both standard or adapted to fit any individual's specification for both trade and end-users alike.

Located in an ideal position close to Hull docks, we hold anything from 2-ton forklifts through to 200-ton cranes covering every type of handling equipment in between, all able for supply, modification, service, and repair.

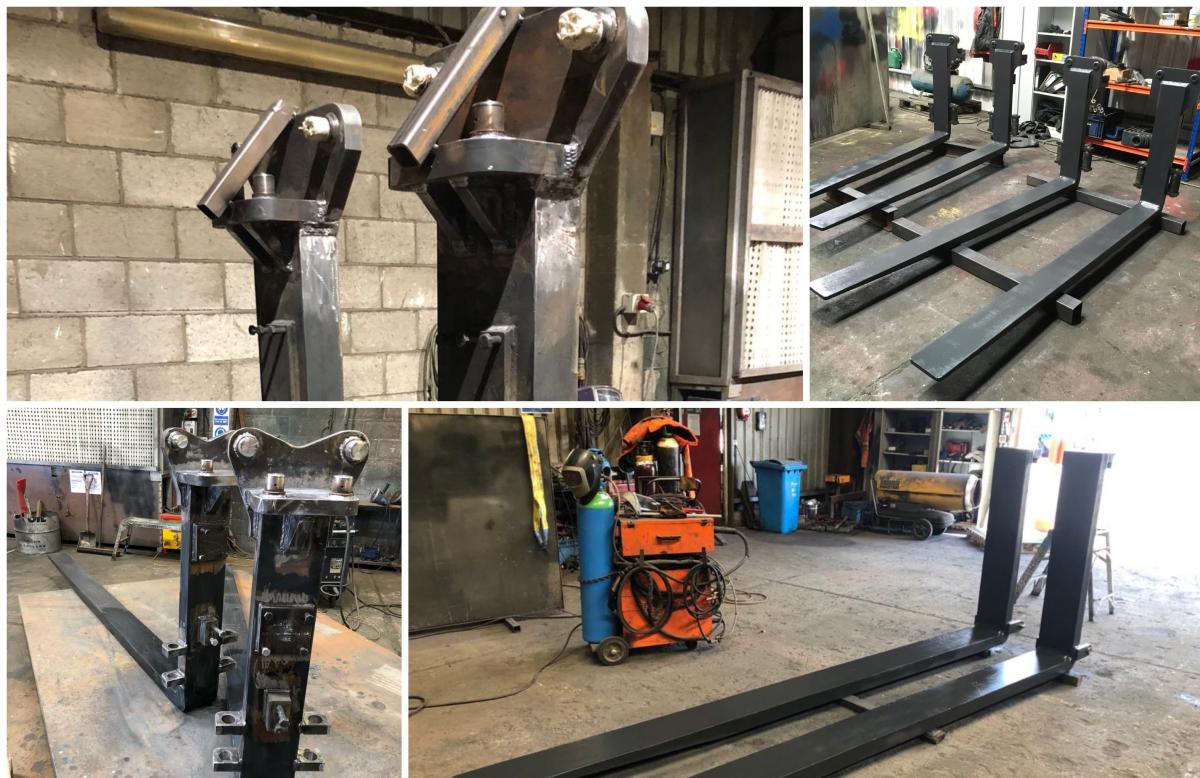

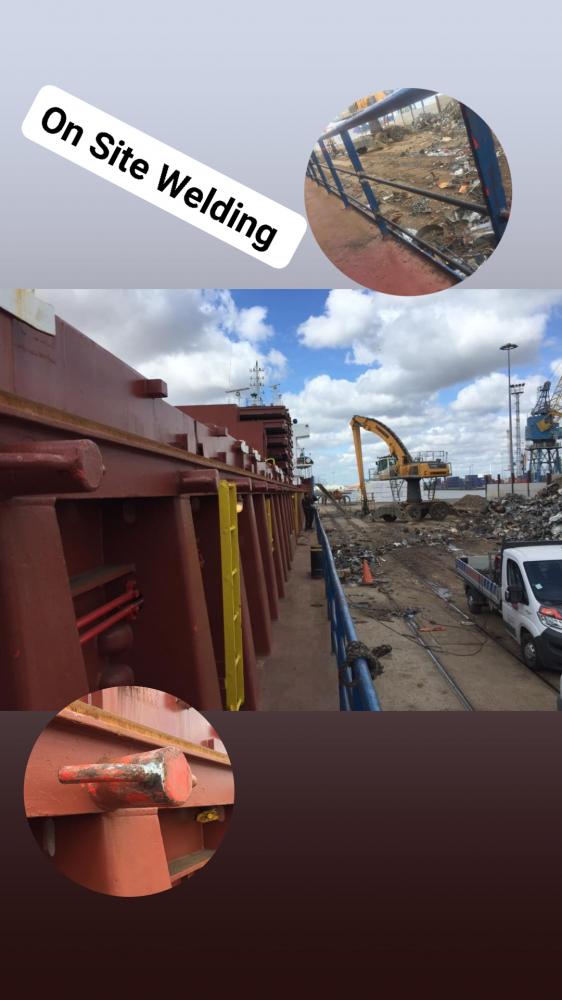

Our Engineerings have decades of Heavy Fabrication experience in both repair and manufacture. As they have gained their experience we have advanced our department,

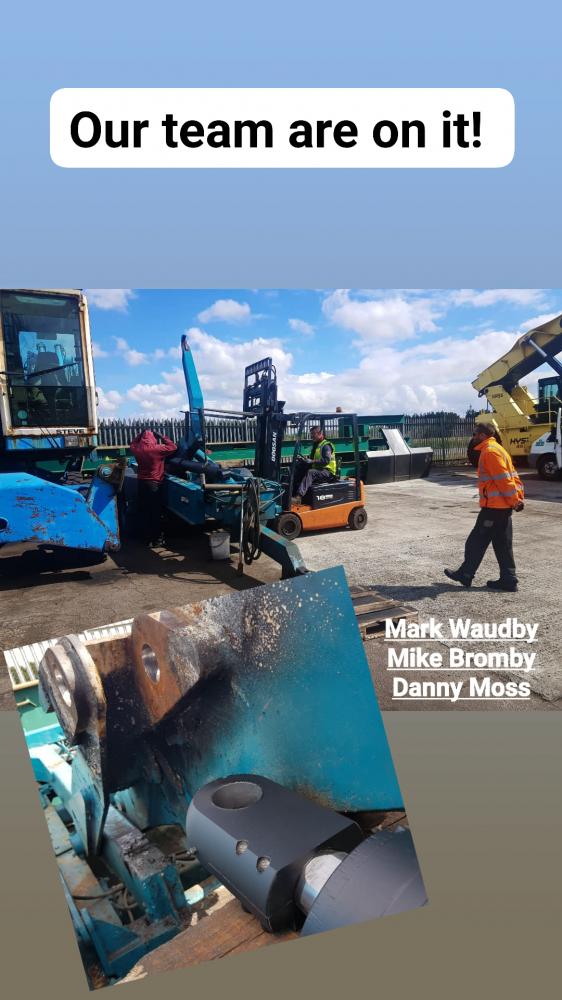

Partnered with our Design Director Danny Moss, our fabrication department completed bespoke industry-changing projects, working with local farmers to complete this Bale Drying Device, but also with our network of material handling customers to aid them with their bespoke lifting requirements,

if you have an idea you want to bring to the table, speak to Danny or Jamie.

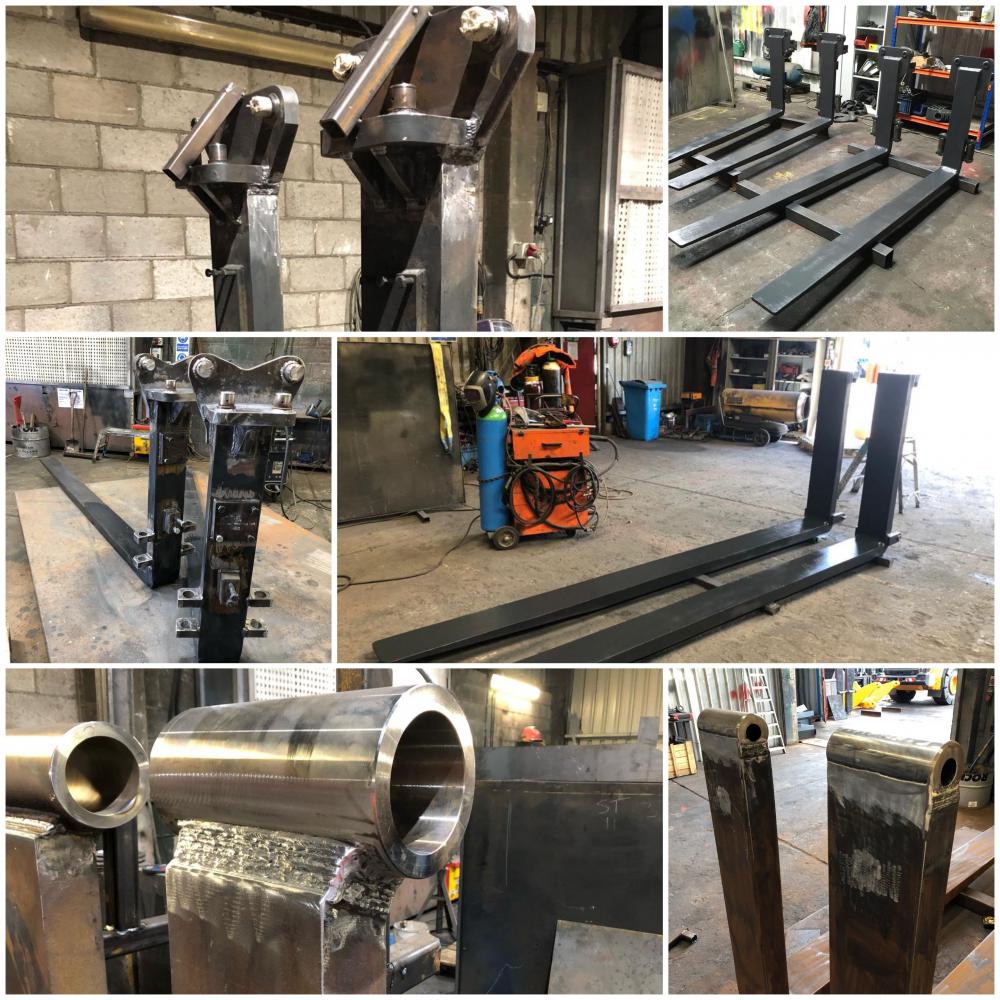

Forklift Mast repairs, Refurbishments, and reductions.

Want to fit through a small workshop doorway?

Need a reduced mast length for cheap transport? especially over short hire periods!

More Mast Cut downs we have completed.

Fork Manufacture.

Our machining department is also known locally as,

Being hydraulic specialists our machining department is able to machine at extremely tight tolerances, and firmly understand the importance of quality component manufacture. Because of this, we are able to extend our services to all range of engineering industries -

WRS MECHANICAL AND SALES DEPARTMENT

WRS MECHANICAL AND SALES DEPARTMENT

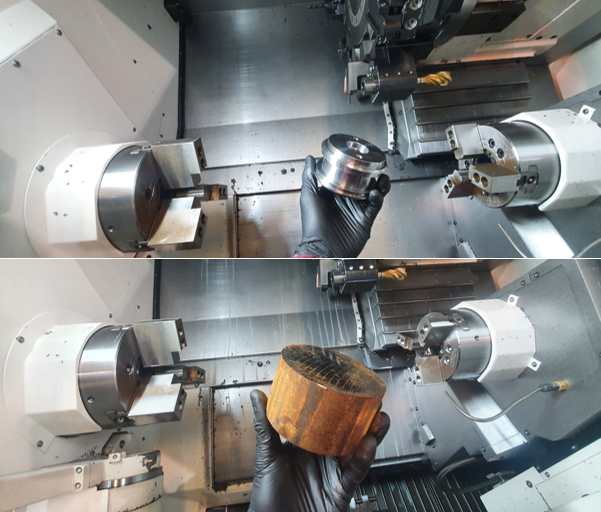

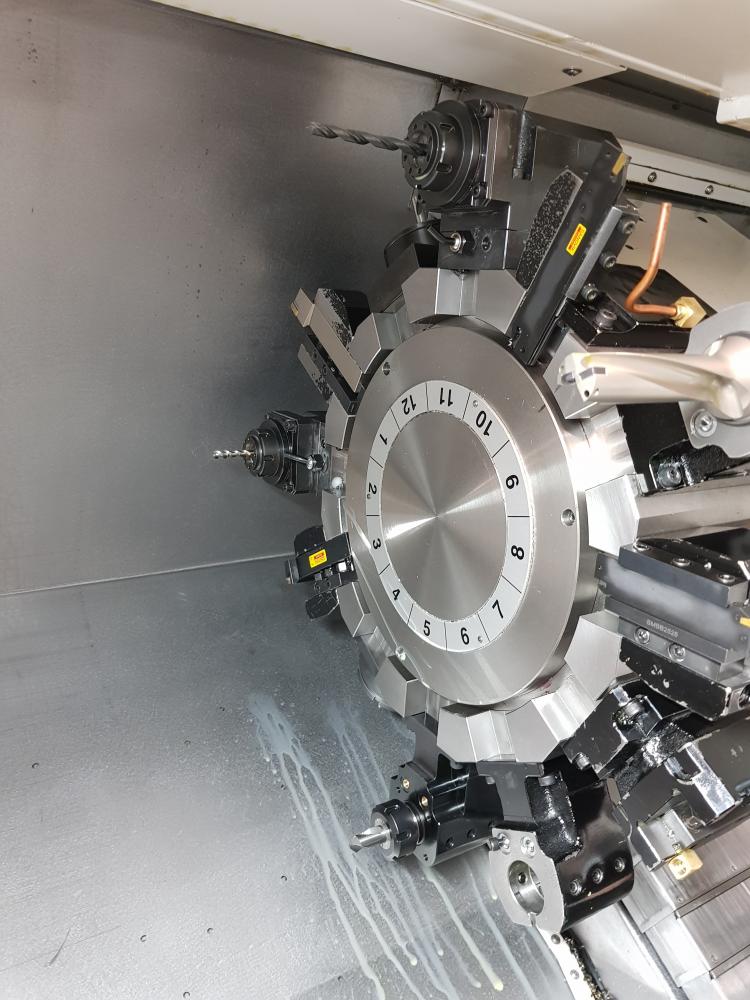

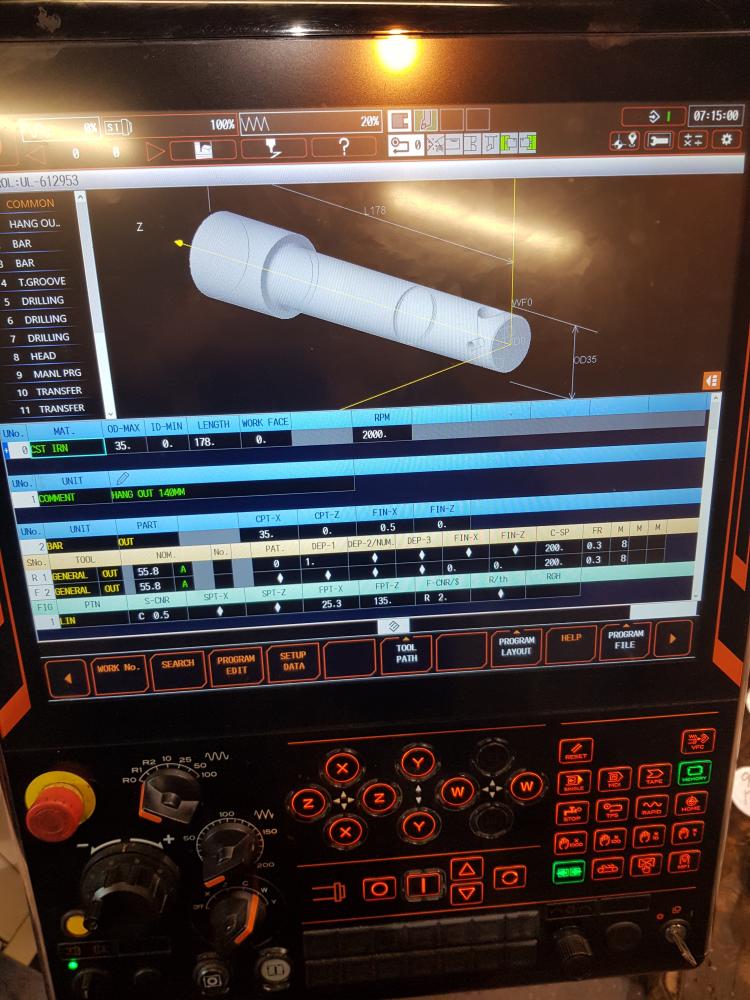

From Raw Billet to complete component our MAZAK 200MSY has a long list of capabilities -

X, Z, C, Y, and W axis!

5,000RPM Spindle speeds + 10,000RPM on driven tool holders,

Off-center Milling Capabilities, coupled with C axis allows for any shaped product to be milled, (within the machining parameters)

Sub spindle transfer, preventing the need for an additional setup,

12 tool position turret,

parts catcher and much much more, see our video below!

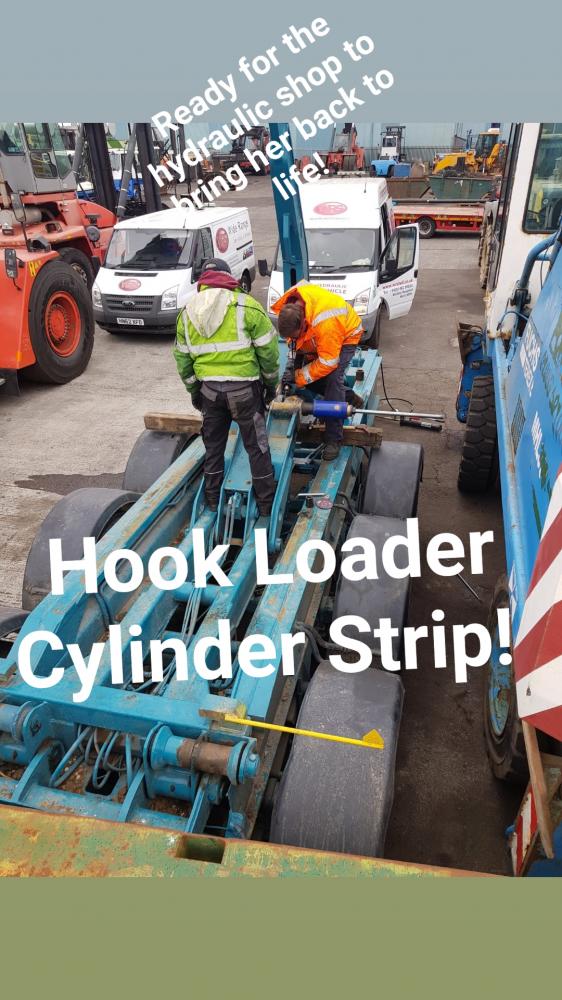

We start with a FREE of charge strip down and initial assessment of your cylinder, this includes –

If you know your cylinder is leaking and can not afford the downtime of an initial assessment, we can visit your site to assess your cylinder, there we can identify the required material, and ensure that we have it on the shelf, in preparation for the cylinder landing with us, this reduces our already fast turnaround time to an absolute minimum, hitting NEXT DAY Cylinder repair times.

Our Cylinder Repair Process –

Technical Design,

Here we assess your cylinder for causes of the failure, be that contamination, over pressurization, or simply misuse, there are countless reasons. After identifying the cause, we can improve and enhance your cylinder's performance, ensuring its future longevity.

Machine Shop,

This is where we use our range of machinery to manufacture your required cylinder components, operating the latest technology in CNC, and high-level capacity for larger cylinders. (SOON TO HAVE A 6METER LONG LATHE BED)

Utilizing our 3-meter manual lathe for weld concentricity assembly. check out the pictures below.

Assembly and pressure testing,

Cylinder components are professionally cleaned of contaminates and are expertly inspected to ensure a smooth assembly and future disassembly. Once the cylinder is built, we perform rigorous testing to suit the customer's specification, testing upwards of 10,000PSI.

Cylinder Paint,

The final stage is our high-quality cylinder paint, protecting our customer's cylinders with hardwearing enamel paint. Following exact customer specifications upon request.

Remember –

We have a fully component fabrication department to aid with any cylinder-associated repairs, for example, bent cylinder links, warped mast sections, twisted digger arms.

Oil and Hydraulic Hose Replacement -

if your system has lost oil due to a Cylinder or hose failure, we stock high-grade ROCK OIL and have over 2,000 hydraulic fitting and devices available on the shelf.

contact us today -

Wide Range Services Ltd

Staithes Road,

Hull,

HU12 8DX

Tel: +44 (0)1482 898261

Fax: +44 (0)1482 587271

Email: enquiries@wrshull.co.uk

Josh - 07801746513 Josh@wrshull.co.uk

watch our cylinder repair video below -

WRS has been machining precision components for the material handling industry for years, expanding upon the original company, Northfield engineering hydraulic specialists, acquired by WRS in 2006, since then WRS has continued the effective hands-on management of Danny Moss, transferring his engineering expertise across the Whole of WRS, supported by machine shop manager Josh Firth, both now Directors of WRS.

Building upon our machining services we have increased our capabilities in CNC, offering production 5 axis machining services, with second spindle capabilities!

With Danny developing his skills in Design and diagnostic, he has advanced WRS into bespoke manufacture, helping to find solutions for industries across the world, specializing in cylinder design.

Whilst Josh has developed the machine shops CNC department, managing production stock, reducing customer prices, and ensuring quality parts are delivered on time.

We like to work closely with our customers, ensuring they receive a service that best suits their needs, working together to meet target prices, allowing our customers to remain competitive within their market.

For the forklift industry –

For material handling leaders –

For plant machinery industry –

For local agriculture –

Using our collective knowledge and industry understanding, we confidently serve our ever-growing customer base, producing high production parts, operation-specific cylinders, and bespoke equipment manufacture.

A growing number of businesses are now making the move over to a renewable energy supply. More than a hundred of the world’s most influential companies have now made a commitment to shift to renewable power. it's about time we joined them.

Moving with the times, we have decided to adopt a greener future for ourselves and for the business, starting with moving our electricity provider. We believe that it's now necessary for WRS to take steps towards a brighter future for our planet.

we are not only looking at our energy usage, we are also working towards a green future regarding our waste management systems. At first, we implemented a single cardboard waste skip situated at the front of our workshops, here to correctly dispose of all office waste and overpackaged delivery goods.

But this skip quickly became the fastest filling skip on our site. We immediately found ourselves investing in additional cardboard skip, now used across all our engineering departments, further reducing our companies waste.

machining complete parts, including full milling capabilities, on and off centerline! completing complicated parts in a single part load. From the main spindle, our machine can automatically transfer to the second spindle to fully complete your complex parts.

Competitive rates!

Stocked parts for immediate call-off!

Various component batch orders!

Further reduced prices on large orders!

Free quotations!

Unparalleled customer support!

Josh 07801746513

Josh@wrshull.co.uk

see picture

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

After receiving a call from a local shipping company, regarding a very urgent hydraulic repair, our director Danny moss and chief hydraulic engineer John Carter headed to the site within the hour, all documentation ready to go.

Once on-site diagnostic began, and after a short while the hydraulic issues were identified, solutions found, and the required work underway.

After a quick trip back to our site for some precision machining, just a 5-minute drive from Hull docks, we were able to have the valve inlet and outlet ports re-machined to ensure a sealing face, after which our engineers returned to the site, refit the valve and complete with final testing of the chain anchor hydraulic.

within hours our customer's vessel was ready for its evening departure. Another hydraulic break down complete

If you are in need of hydraulic assistance, give us a call – +44(0)1482 898261

For the latest visit our website - www.wrshulluk.com

for more engineering capabilities - www.wrshulluk.com/eningeering

Celebrating 20 years of WRS incorporating WIDE RANGE LIFT TRUCKS, Northfield Engineering hydraulic specialists, Initial metals, and east coast fluid power.

The first seven years saw a consolidation of operations culminating in 2012 with the completion of the new machine shop and mechanical workshop. WRS now has 14,000 square feet of workshop including a fully equipped machine shop, hydraulic repair shop, two forklift refurbishment workshops, and a fabrication & welding workshop, along with 2 acres of yard storage, allowing us to expand our equipment sales. All of this combined enables WRS to supply equipment both standard or adapted to fit any individual's specification for both trade and end-users alike.

Located in an ideal position close to Hull docks, we hold anything from 2-ton forklifts through to 200-ton cranes covering every type of handling equipment in between, all able for supply, modification, service, and repair.

2020 has been a roller coaster for all of us at WRS with Brexit and COVID-19 not exactly going to plan. Yet our Director and part-owner Andy firth, along with the support of his team, have managed to maintain WRS’s GOLD standard in health and safety! Proving that even when the world is in crisis, our Health and Safety responsibilities remain an absolute necessity within our business plan.

see our certifications.

With the full cooperation from WRS’s family of employees, we have been able to improve upon our already extensive labyrinth of health and safety procedures, policies, and practices. Coming into our third year of GOLD Standard! Ensuring we provide a safe workplace for ALL.

2x 16 tone mast conversions, fully manufactured, assembled and tested in house. Amazing to see a job like this coming to its completion, great work by our team, all departments pulling together helping each other out. We are the experts in conversions give us a call today.

see pictures.

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

see picture.

BIG THANK YOU to all the gentlemen at WRS who have pulled together all month, growing their facial hair and putting their hard-earned money towards men's health charities. Helping to fund medical research, supporting groundbreaking tests and trials, aiding life-changing men's health programs, and funding new innovative treatment services.

The UK has again entered Lockdown. And we have responded, adding further measures to our site, including daily workshop & office disinfection, weekly deep cleans, and complete visitor segregation, We remain open and operational knowing our Staff and visitors are safe.

We are determined to ensure all our customers can continue to rely on us for their vital services, Whilst firstly prioritizing the safety of both our staff and our customers. Here's our newest addition to our already extensive health and safety measures -

Recently adding - Perspex trade counter screen, additional visitors sanitizes, and a reviewed entrance for visitors. All whilst maintaining a HIGH-level of HR & Health and Safety -

Reach Stacker back axle in need of a full rebuild, due to a complete bearing collapse on their right-hand side, an easy task for our experienced engineers.

Starting with the weld up and machine boring of the bearing seats, Hitting H7 tolerances to achieve the perfect fit for our 180mm bearings.

This time bored out and sleeved to suit their 100mm pins, with the help of our on-hand precision machine shop.

All in a day's work for our Team, for all your Heavy Handling Equipment repairs, contact us today -

Enquires@wrshull.co.uk

and visit our engineering page to see the full extent of our capabilities!

Kalmar DCG 80-45ES6 SOLD, stripped, cleaned, packaged, and on its way to Australia.

After previously purchasing machines for their Hull and Dublin depots, they chose to contact us directly to further assist with their material handling requirements, this time for solutions at their new Sydney depot.

check out the exact machine details here -

https://www.wrshulluk.com/kalmar-dcg80-45es6/166

and to see operations check out our video -

Hyster Company’s empty container handler can help port operations reap time and cost savings by handling two empty containers simultaneously. This double-handling capability provides particularly powerful advantages as organizations scale to handle growing demand while maintaining targets for efficiency and cost.

Double container handling can help improve throughput and reduce congestion at ports – both inside the terminal and on roads. This helps reduce wait times for over-the-road freight trucks and optimizes traffic flows in and out of terminals. Double empty container handling can increase throughput by up to 30%, reducing cost per container moved and boosting profitability.

our range of available empty handlers -

For a personal deal on all our current stock contact our sales team!

Reach Stacker Cylinder Repair

using our 3M lathe we can handle huge cylinder repairs like these -

from removal -

Repair -

Paint Process

Refit -

Heavy Equipment Repairs are what we do best!

Please note all defective parts are available to be viewed by the customer and can be returned with the machine. The machine is also available to be inspected if you wish.

The machine will be given a final day’s test on Monday in the yard then will be available to collect from Tuesday onwards providing we find no issues on test.

for information on all our services visit our engineering page here.

moving on to a happy customer in the midlands.

For all your terminal tractor sales, email Jamie@wrshll.co.k or call him on 07801746514

full range of terminal tractors here!

here at WRS, we offer the ability to secure a personal deal, one which best suits your needs, including any additional work to the machine you require, or an aftercare service that ensures your productivity. We value every customer meeting their every need with our engineering division in collaboration with 100+years of material handling experience.

We have X3 HIGHLY sort after Reach Stackers now on stock ready for resale, and when it comes to reach stackers, the most cost-effective choice is a Hyster Reach Stacker. It is known for its competitive price and low costs for running and service, making it the perfect used machine of choice. The only thing missing is your personal seal of approval, which we can help with.

We offer onsite test drives, where you can sit with our directors and we can shake hands on our agreed deal! (how we prefer to interact with our customers) or if you cannot make it to us don’t worry, we can perform live test drives displaying all the vehicles capabilities, emailed photos, machine documents and any other information you need for your purchase, all provided by Jamie Firth director of sales. When choosing WRS you have a team of 3 maximum sales men, 2 of which are owners! All holding the ability to sell you a machine instantly.

Every container yard must bring down the cost per box moved to stay competitive in this growing, fast paced industry, And we have 4 on stock ready for purchase! These machines are going fast so contact us today for further details, certificates, 20+ photos, videos, certificates, AND MORE.

https://www.wrshulluk.com/stock

Jamie@wrshull.co.uk for sales!

One of our highly valued customers who are widely regarded as the UK's leading Hire company for mechanical handling equipment had one of their SMV Heavy Duty Forklifts delivered to us this week for a complete overhaul, After spending time at the Molten steel works.

Our experience fitters removed all components in need of repair. Cylinders, into our specialist Hydraulic department-NORTHFIELD ENGINEERING for professional refurbishment, Forks and Carriage into our Fabrication department, and numerous other repairs through or Wide Range Lift Trucks department.

Our customers own a range of heavy handling equipment operating in the toughest applications across freight, ports, inter-modal terminals and other heavy lifting sectors, choosing WRS for their heavy handling equipment repairs, Utilising our complete forklift engineering services. Here's the truck ready to be put back to work!

For enquires please contact Jamie - Jamie@wrshull.co.uk

Busy day for Jamie and our yard engineers today with new stock arriving X3 Hyster empty handlers, and one SMV reach stacker landing to undergo some repairs in our engineering departments. We offer total solutions for your heavy lift trucks, container handlers and reachstackers holding a huge stock of varied truck manufacturers, allowing our customers the chance to come in and find out for themselves what truck suits them, or more importantly which truck or trucks, best fit their solution needs.

From our machine shop where we manufacture all required components, Fork head stubs, along with their profiles. Rollers and pins manufactured and then hardened for long term use.

Also producing cylinders in house as side shift ram on our newly manufactured carriage

Moving into our fabrication area, welding up our forks then undergoing testing to ensure full customers satisfaction.

assembly of the newly produced carriage to our Fork truck

Rigorous testing and inspection

complete ready for shipping to our customer

Here are our posts over the last 2 months, we like to keep as up to date as possible with our customers, suppliers and anyone else who is interested in our company, all are welcome to join us.

We post pictures of our day to day work on our social media outlets,

See our facebook for engineering https://www.facebook.com/joshwrshull/

See Jamies linkedin for the most recent stock arrivals and updates on current stock - https://www.linkedin.com/in/jamie-firth-984a6a10b/

A returning customer contacted us to see if we could help with his unique lifting requirements, he knew that we excel is finding solutions for these kinds of problems.

Once we understood the ins and outs of what he wanted to lift, we where able to fully design, manufacture, test and paint new forks to fulfil his lifting needs.

These where some 3.6M long Forks designed to easily mount onto his existing carriage.

We even visited his site to mount test and ensure complete customer satisfaction.

We ensure that our customers are 100% happy with our work and offer a fully fleshed after sales service, with the added Support from each of our specialist departments. We believe this is why of customers keep returning to us.

see the home page of our website for the latest!

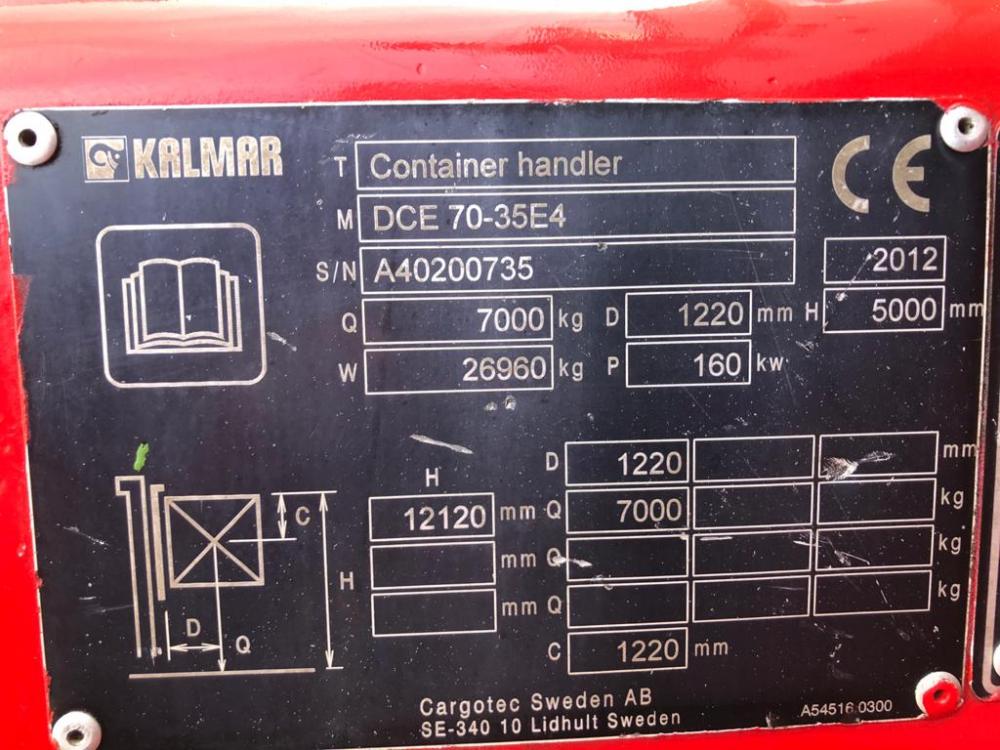

KALMAR DCE70-35-E4

sold to a returning customer in Ireland! after a visit our customers where set on this truck, We allowed for 300 hours bring this truck up to our customers required standard, replacing and refurbishing all areas of the truck through the support of our fork truck specialist companies.

Our experienced team fully cleaned the truck, inspect all aspects from Add blue system repairs to replacing grip tape on steps, ensuring every part of the truck is functioning proper, safe to operate, and ready to get out to work!

Once repairs have and the truck had been fully tested our customer returned to ensure they where 100% happy with our work.

visit our engineering page to see how we can be of service .

https://www.wrshulluk.com/engineering

or visit our stock page to see the latest stock,

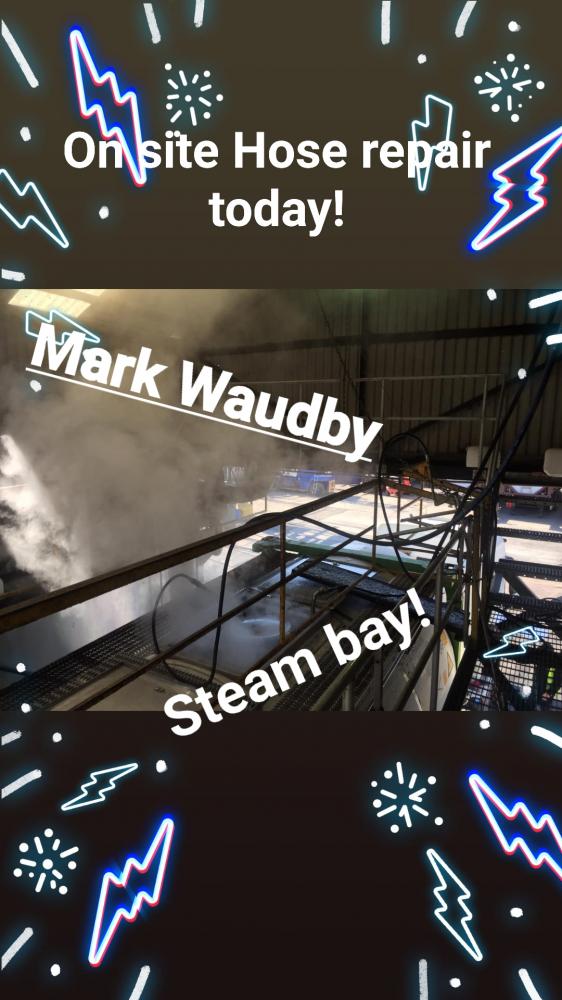

With the Combined efforts of Northfield engineer and East Coast Fluid Power we are able to offer our local industries a complete hydraulic service, including Hoses repair and replacement both on site and in house, Cylinder Repair and Manufacture, machine Diagnostic on site and in house, with a full stock of hydraulic devices and fittings ready to resolve any fault we find.

When your in need of a hydraulic hose repair/replacement, if its possible to bring your hose into to us we will fix it immediately, Walk in hoses take priority! while you are here we understand that with a failed hose, there is usually some lost oil, and we have all the essential oils on stock ready.

With our mobile Van on call 24/7 we can ensure that all our customers are support ALWAYS, and with our fully equip workshops we can get you back up and running no matter what! You will also have the full support of our partner companies, Initial Metals and WRLT allowing us to expand on our hydraulic services with mobile welding repairs and on site Fabrication.

Having the combined services of each company allows us to fully support local industries with their material handling machines. We can offer you this service too!

A long term customer of ours had their Manitou Telehandler fail on site, it was diagnosed as a fault with their boom cylinder. After the call our mobile hydraulic engineer Gavin visited their site, and with the help of their own site engineer we stripped the cylinder from the machine, then transported it back to our workshop for a full Professional repair.

when the cylinder landed it was over to Mark our experienced in house Hydraulic Engineer, he Fully Stripped the cylinder, Inspected the damage components to determine what repairs where needed, along with identifying the seals required. Having the cylinder in our workshop means this process can be done professionally, ensuring that hydraulics number 1 killer CONTAMINATION, is excluded from the start of the repair.

Time for the Machining! The Tube was completed on our 3Meter Colchester machine, Whilst the Rod, piston and gland where polished using our XYZ Machines. Following our Rigorous repair checks ALL machined parts where fit tested to their Mating parts, steam cleaned to remove all CONTANIMENTS, and with their paper work filled out they where moved onto weld, build, test and paint.

Once back in the hydraulic workshop, the tube was welded in our Purpose built welding bay, where fumes/CONTANIMENTS are contained. Another cleaning process is complete ready for the final build and Paint. Pained using our hard wearing enamel paint, ready for some hard years work!

Back into the mobile Hydraulic van! head to site for machine mounting, Once mounted the machine was fully tested to meet our customers satisfaction.

Another happy customer!

Today our Wide Range Lift Trucks team spent their afternoon Preparing for tomorrows customer inspection visit. We know how important it is for our buyers to feel completely reassured that what they are purchasing is exactly what they require. With over 40 years of forklift trading advise on finding the best solutions and a range of stock trucks you can test for yourself, you can be sure your are making the right decision.

ALL four of their trucks are lined up ready for full inspection, and with our 2 acers of yard area we can FULLY demonstrate the trucks capabilities, which we can also do via a full DEMO video for those who can not visit themselves. Although those who can visit us have the opportunity to connect with our entire team from the owners Andy and Ian, who are always on hand, Jamie Head of our forklift sales and the engineers themselves who have restored their trucks ready for sale.

We are an open book here at WRS and welcome visits anytime during open hours from 08:00-17:00 we may not be quite as well prepare as this, but we will ensure you receive the same service. Starting with a hot dink and a chat in our comfortable office, whilst the trucks you are interested in are brought out for your inspection.

if your interested take a look, here is our most recent stock video, and for our newest arrivals visit our website - stock page https://www.wrshulluk.com/stock

Expanding upon our lifting equipment modifications, we repair and manufacture a range of equipment, including full fork manufacture & refurbishment, complete bucket refurbishment, Complete fork truck carriage manufacture, repair and modification, all forms of port trailer equipment, the list goes on!

another Mast reduction below done to allow entry into a small workshop -

We can also modify specific existing carriages like this one -

Our country is currently under strict measures to ensure our peoples safety, to which we are following to the letter, ensuring our employees, customers and the nation is kept safe. While doing so we are maintaining our services in order to keep our many important industries operating.

OPEN FOR BUSINESS

Click the link below to see our latest and contact us for enquires

Kalmar 150-12 Mast shorten from 4.6m 3.8m, we can do this to our full range of stock, from 1 tone to 50 tone trucks!

Empty handlers stripped down loaded to transport and on it's way to our customers in Ireland, one to Cork and two to Dublin.

Trucks landed built up ready to go!

The last of the three leaving the yard

Leaving the yard on a late night, ensuring everything is as it should be before she goes out!

Engineering Suppliers Visit

Great evening, finding new solutions to difficult to solve problems.

carriage in fabrication

carriage in fabrication

carriage in machining

carriage in Paint

carriage wrapped ready to go.

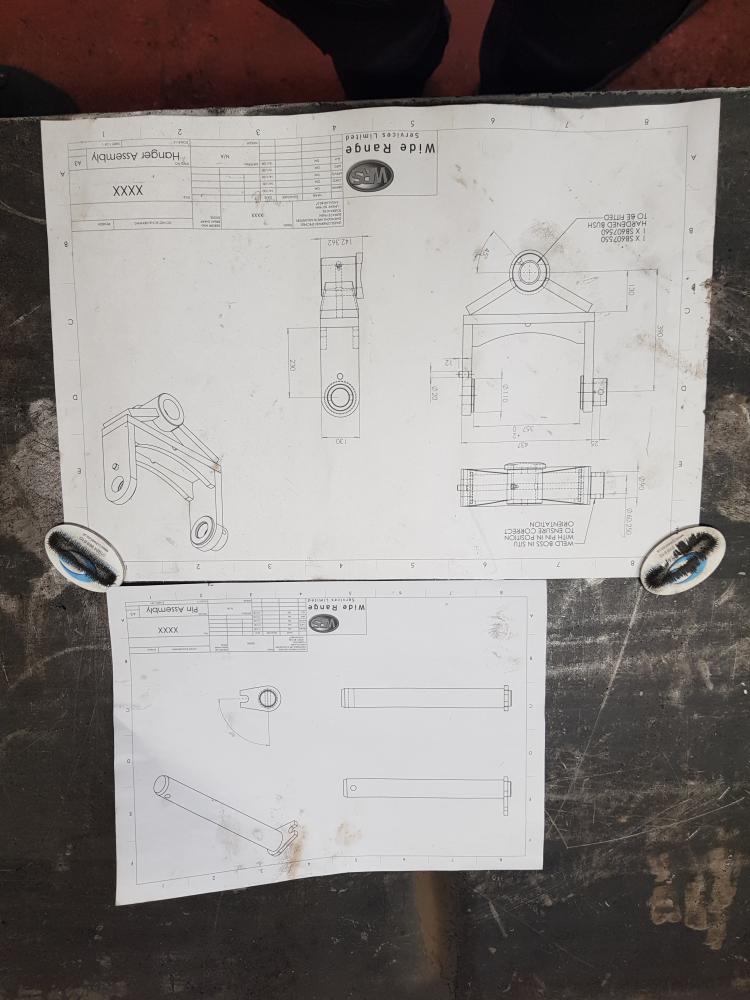

Designed, manufactured, and certified ready to go!

We have specialist technician Danny Moss experienced in bespoke SOLID WORK design and over 10 years of knowledge directing our hydraulic specialist company. Proving his understanding of the waste management industry by designing and manufacturing this scrap grab hanger!

Another 2 off qulaity used Kalmar DRF450-65C5X reach stackers on the way to a good returning customer in belgium with a final destiantion of vietnam.

new machine arriving into stock this week.

SOLD!!!! Kalmar DCE160-12 all ready to leave the yard today onto a new customer.

SOLD forklift with coiul attachement

loaded ready for transport

loaded in front of engineering shops

G.C.S. Johnsons ready to go!

Forks loaded ready to be transported

SOLD!!! SMV32-1200B leaving the yard today onto another new customer with a customized coil boom attachment modified to customer specification

Full system refurbishment. Cylinder rods and reseals, new pack hoses, filters and system clean with a buff and paint with zinc free paint, meeting our customer requirements. great work from team here

A customer of ours brought us a leaking cylinder. Our team tested the cylinder and found the leak to be situated on the bung weld, so we had the port taken off, the old weld machined back and tube prepared for a penetrable reweld by our Professional tube welder, as you can tell by his quality. the ram was then tested cleaned up and repainted. another happy customer.

Blog Content here

SOLD!!! package of 3 DRF450-65C5X reach stackers

Another great effort from the lads this week full stripped down and loaded 3 DRF450-65C5X reach stackers. Now on the way to a trader in Europe.

loaded right hand side

loaded in front of workshops

loaded on way out of yard

final loading operations

Johnsons lad ensuring secure load

securing truck down

secure ready to transport

counter weight loaded onto transport

spreader attached loaded ready for transport

parts loaded onto container transport

stacker arm loaded

strapping down

Blog Content here

Title

Blog Content here

Truck loaded and ready to be transported.

Title

Kalmar DCE160-12 leaving the yard today on its way to a local haulage company to assist with the increasing work load. customer was a pleasure to deal with and even gave us a call to say how happy he was with the machine when it arrived.