At Wide Range Services Ltd, our Fabrication Department specialises in industrial welding and custom fabrication, with a focus on forklifts, material handling equipment, and heavy machinery modifications. Whether you need cracked forks repaired, new ones fabricated to spec, or a forklift mast shortened for tighter site access, our team delivers safe, certified, and long-lasting solutions built around your equipment.

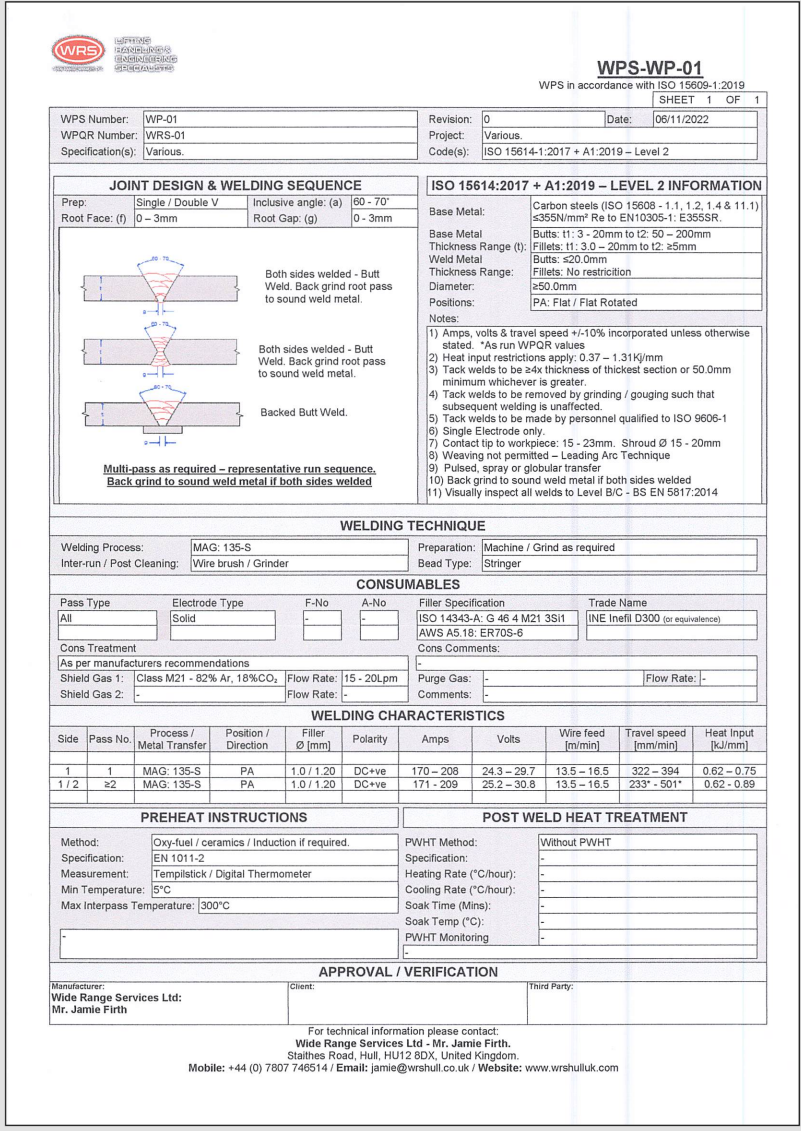

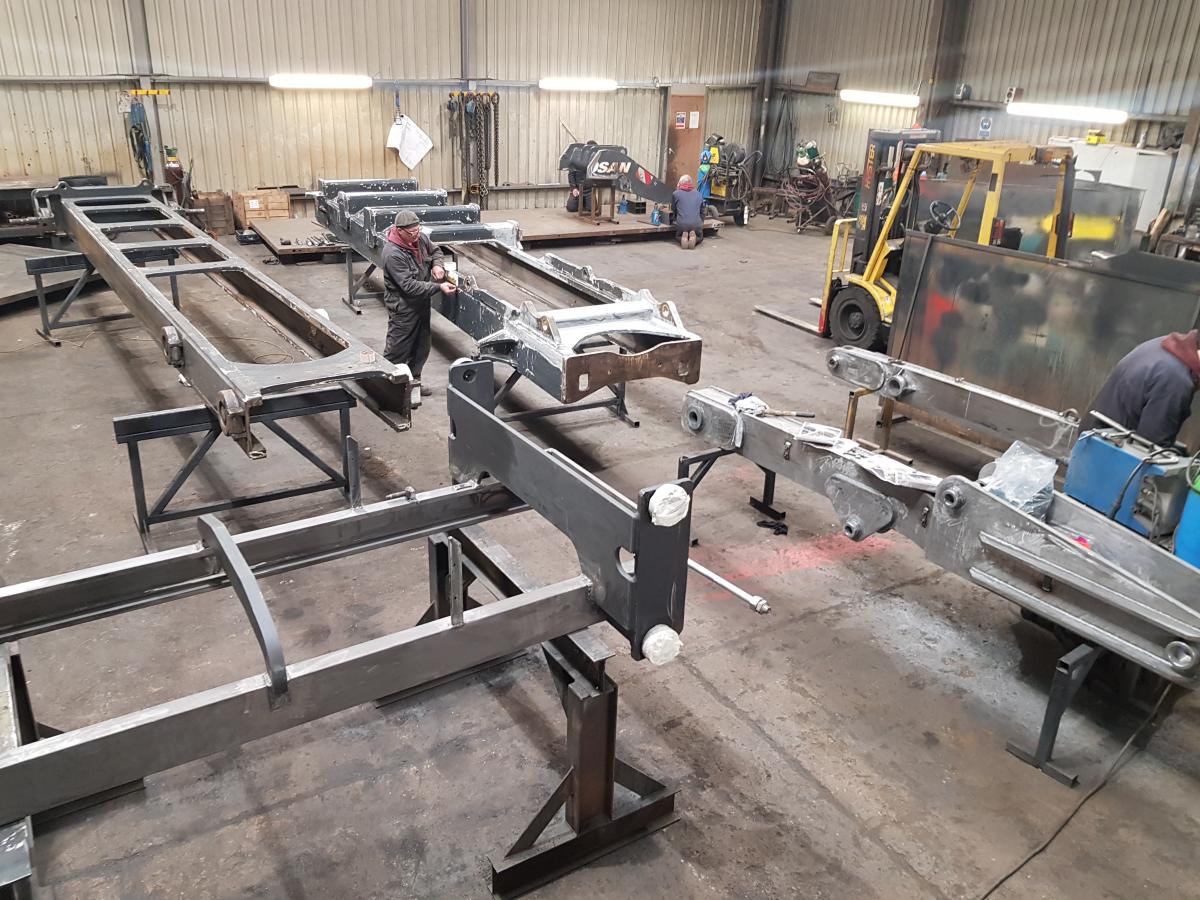

At Wide Range Services Ltd, our fabrication department is equipped to handle everything from small bracket jobs to complex structural modifications. We combine skilled hands-on fabrication with solid engineering practices, and every weld we produce follows strict quality and documentation standards.

We provide expert line boring services for heavy plant, forklifts, and industrial machinery. Whether you’ve got worn pivot points, elongated pin holes, or distorted bore centres, our line boring service restores critical fits with accuracy and strength, keeping your equipment safe, reliable, and within tolerance. We offer both in-house and mobile line boring, allowing us to carry out precision repairs at your site or at our Hull-based engineering workshop.

We specialise in the fabrication, modification, and repair of forklift forks and fork attachments. Whether you need a set of custom-length forks, repairs to worn or damaged forks, or bespoke alterations for a specific application, our in-house team delivers safe, certified solutions built to handle real-world loads.

We offer a specialist mast reduction and shortening service for forklifts and material handling equipment. Whether you're working in low-clearance buildings, tight warehouse aisles, or need a modified mast to suit a specific site or load requirement, we can adapt your existing equipment safely and professionally.

All mast modifications are carried out in-house at our Hull workshop by experienced fabricators, with full support from our machining and hydraulic departments where needed. The result is a structurally sound, fully functional mast that meets both your space constraints and operational demands.

We design and manufacture bespoke forklift carriages for standard and specialised material handling equipment. Whether you're upgrading worn or damaged parts, adapting a machine for a specific application, or building a custom forklift solution, our team can deliver a carriage that fits perfectly and performs reliably.

We design and fabricate a wide range of forklift and material handling attachments to suit your specific tasks, loads, and site conditions. Whether you need fork extensions for awkward loads, lifting jibs for non-palletised materials, or bespoke attachments for unique handling challenges, we build attachments that are safe, strong, and made to last.

We provide reliable and flexible on-site welding services for customers who need repairs, modifications, or support carried out directly at their premises. Whether it’s emergency repairs on heavy equipment, structural work on plant, or installation of custom-fabricated parts, our mobile welders come prepared with the tools and experience to get the job done safely and efficiently.

Our mobile units are equipped with MIG, TIG, and Stick (MMA) welding gear, allowing us to work on a wide range of materials and environments — from construction sites and ports to factories and workshops.

We offer a full bespoke design and fabrication service, working closely with engineers, site managers, and business owners to turn their ideas into fully functioning components, structures, and systems.

Using SolidWorks 3D CAD software, we bring concepts to life with precise engineering drawings, visualisations, and technical detail before a single part is cut or welded. Whether it’s a one-off prototype, a modified assembly, or a site-specific solution, we deliver custom-built results that are practical, durable, and fit-for-purpose.