Precision Engineering, Built to Perform

We provide a full in-house machining service, delivering high-precision work across a wide range of industries. Whether it’s a one-off repair or a complex production run, our experienced engineers are equipped to deliver reliable, accurate results every time.

We operate under an approved weld procedure that complies with ISO 15609-1, and apply the same level of care and control across all machining operations. Every job is accompanied by a detailed job report and compliance photos, providing full transparency and traceability for your records.

This process ensures a high-quality, honest service, giving you confidence in the work we've done and helping you stay compliant with internal or third-party audits.

We understand the downtime and disruption caused when critical parts fail, especially when OEM components are no longer available or have long lead times. That’s why we offer a rapid replacement part service, manufacturing high-quality custom components in-house to keep your equipment running.

Whether it’s a complete replacement hydraulic cylinder or a worn-out plant machinery component, our machining team can reverse-engineer the original, working from physical samples, technical drawings, or simply the problem itself.

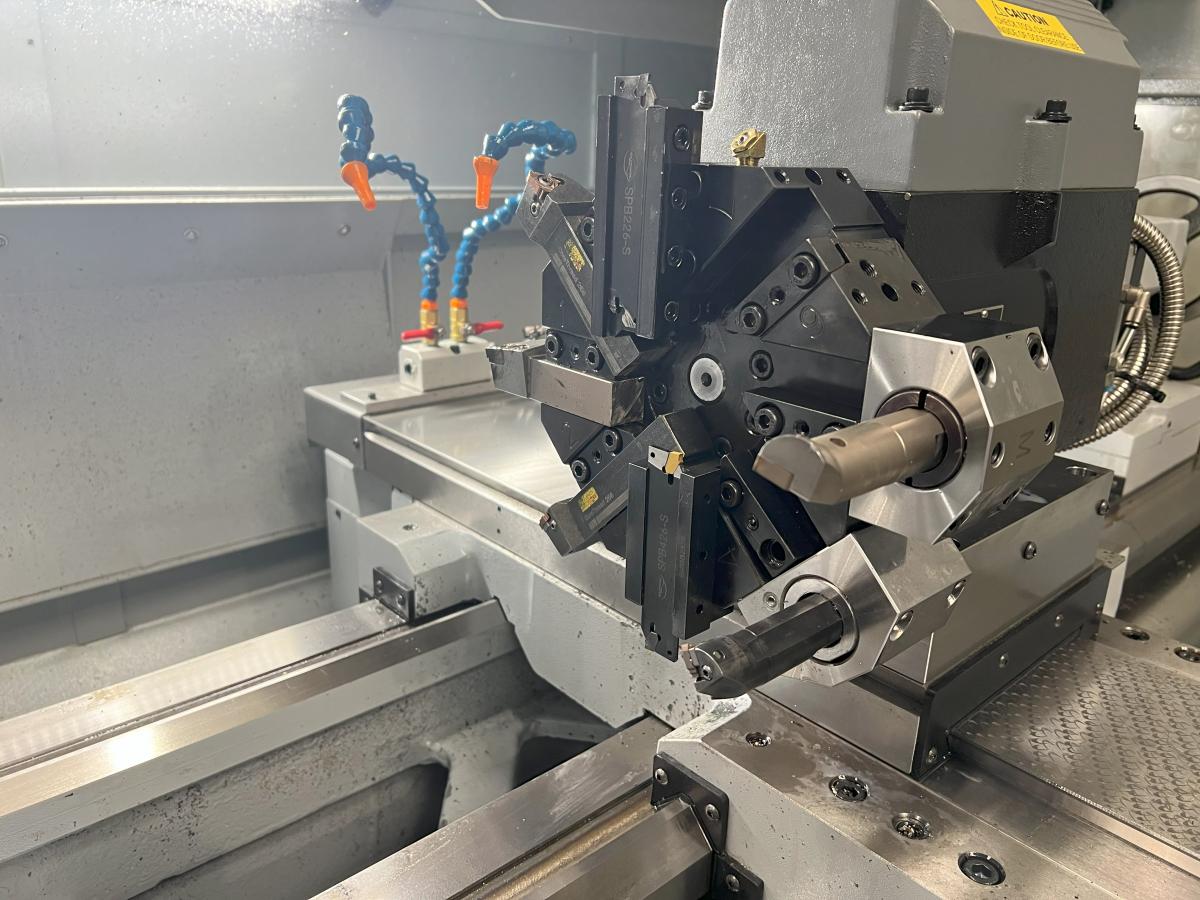

We operate a well-equipped machining workshop capable of handling everything from intricate components to large-scale industrial parts. Our machinery is selected to suit the heavy-duty demands of the industries we serve, with the flexibility to produce both bespoke one-offs and high-volume production runs.

✅ Experienced engineers with hands-on industry knowledge

✅ Fast turnarounds and emergency repair availability

✅ Large-capacity lathes and mills

✅ Accurate machining backed by real-world fitment know-how

✅ Integrated reporting and photo documentation for every job